In the competitive world of sign-making, vehicle wrapping, and display graphics, the quality of the final product determines client satisfaction and your business reputation. You've invested in a cutting-edge printer, but the finish line isn't the ink drying—it's the lamination. Without a professional-grade protective layer, your vibrant graphics are vulnerable to UV damage, moisture, and abrasion, drastically shortening their lifespan.

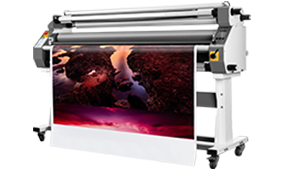

This is where the Wide Format Hot Roll Laminator becomes the non-negotiable hero of your print shop. These commercial-grade machines are essential for applying durable, flawless films across large surfaces, transforming a printed sheet into a high-value, long-lasting asset. However, choosing the right machine is a significant investment, and the specifications can quickly become overwhelming.

So, how do you ensure you’re investing in the right machine to maximize your productivity and minimize material waste?

This Ultimate Buyer’s Guide is designed to simplify your decision. We will break down the crucial components of these powerful tools, detailing the 7 Key Features that separate an adequate machine from a truly reliable, profit-generating powerhouse. By the end of this guide, you’ll have a clear checklist to evaluate any hot roll laminator, ensuring your next purchase perfectly meets your production needs and drives your business forward.

1. Max. Working Width & Speed (Capacity & Efficiency)

The laminator's capacity must match your widest printer. Always choose a machine 2-4 inches wider than your maximum print size for easier alignment and error prevention.

Speed: Look for variable speed controls (m/min or ft/min). Slow speeds are essential for flawless mounting; high speeds are necessary for cost-effective, long production runs. A superior machine maintains consistent speed under continuous heavy-duty operation.

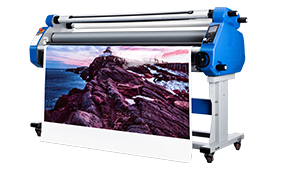

2: Heat Technology & Control (Quality & Consistency)

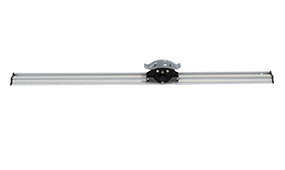

The core of a hot roll system. Prioritize machines with heated silicone rollers over basic heated shoe systems for superior, even heat distribution across the entire width.

Precision: Demand digitally controlled temperature settings (e.g., up to 130°C). This control is vital for working with various media (like PVC vinyl) without causing shrinking or bubbling.

Efficiency: A fast heat-up time minimizes expensive downtime.

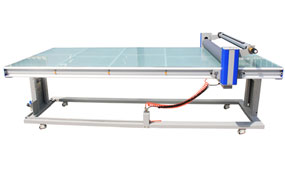

3: Mounting Thickness & Pressure (Application Range)

A laminator must do more than just laminate; it must mount.

Thickness: Ensure the machine handles substrates up to 1 inch (25mm) for rigid materials (foam board, PVC).

Pressure: A robust, adjustable pneumatic or hydraulic system is crucial. Uniform pressure from edge-to-edge ensures strong adhesion and a permanent, bubble-free bond.

4: Ease of Use & Ergonomics (Operator Efficiency)

User-friendly features increase output and reduce errors:

Interface: Intuitive digital control panel with memory settings.

Auto-Systems: Features like auto-grip film loading and ample infeed/outfeed tables simplify handling large media.

Safety: Non-negotiable safety features include emergency stops and laser eye guards.

5: Film Handling & Tension System (Waste Reduction)

Poor film handling leads to costly waste.

Auto-Tension Control: This premium feature prevents wrinkling and curling by automatically adjusting the film rolls.

Take-Up Unit: An automatic rewind reel that cleanly collects the waste liner is essential for long, unsupervised production runs.

6: Durability & Construction (Longevity)

This is a long-term capital investment.

Construction: Look for a solid, heavy-duty steel welded frame for maximum stability.

Components: Ensure the rollers are made of industrial-grade silicone rubber.

Support: A strong warranty and reliable local technical support are key indicators of a quality commercial product.

7: Cold Lamination Flexibility (Versatility)

For maximum utility, your hot roll laminator should include a true cold lamination mode. This dedicated setting allows you to safely process heat-sensitive materials and specialty pressure-sensitive films without risking heat damage.

To secure your print quality and maximize your ROI (Return on Investment), use this checklist to evaluate your next machine. Focusing on these 7 Key Features ensures you invest in a reliable, profit-generating machine that will deliver professional-grade results for years to come.