BRIEF

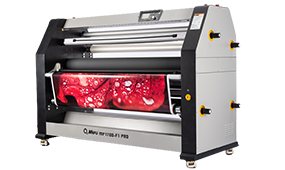

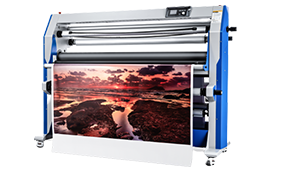

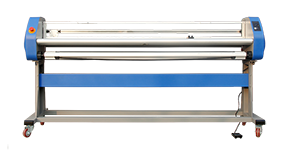

MEFU stands as a premier manufacturer catering to the needs of the Small and Large format printing industries worldwide over 17 years. Our products include Roll laminator, Flatbed applicator, Cutting device, Lamination Film, and a range of Accessories. With partners in over 110 countries, customers can easily find the most suitable products.

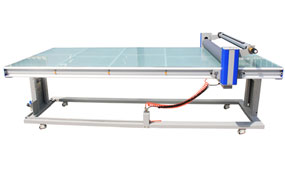

Since its inception, MEFU has been an innovative driving force in the finishing industry. Originally, MEFU introduced the first automated heat-assist laminator, and then successfully made flatbed laminator with revolutionary adhesive system designed specifically for both rigid and flexible materials in 2011.

Amazingly, in 2014, the launched hybrid laminating and cutting machine greatly simplified the finishing process for sign makers by cutting the edges during lamination, further cementing our position as an industry leader.

.png)