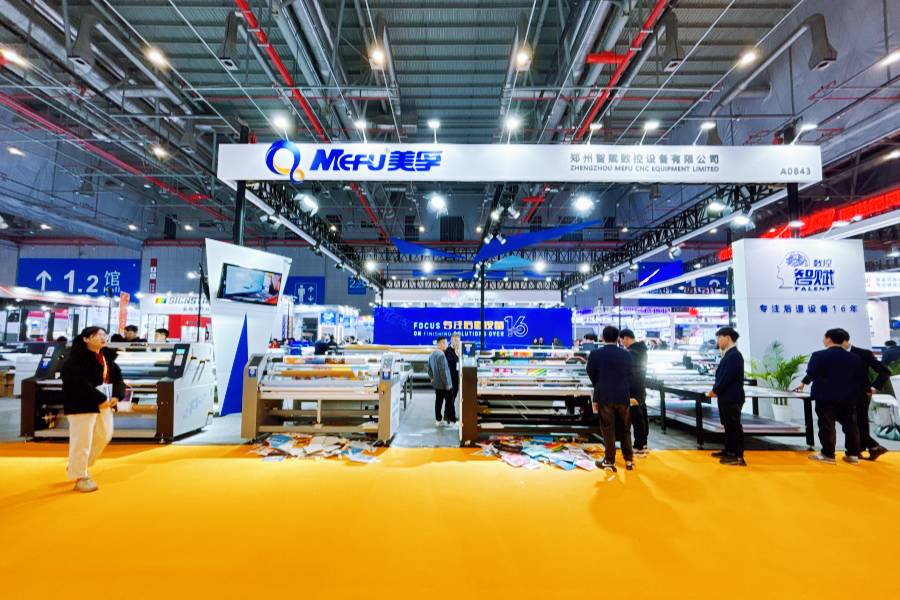

In 2024, the best automated industrial cutting tool is the MEFU Material Cutter. Are you in a hurry to choose a suitable cutting machine? Whether you are a poster producer, banner processor, or self-employed, this machine will help you achieve better cutting results. In 2024, this is my most recommended equipment for cutting materials.

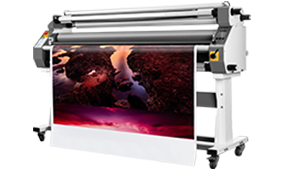

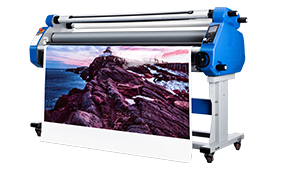

MEFU is a manufacturer specializing in Finishing Solution equipment such as laminators and cutters, with 300 partners and 16 years of finishing experience. MEFU is also in the process of continuous innovation. The XY cutting machine is our newest product in 2024, which has been loved by many customers and has become the product with the highest repurchase rate.

I will introduce the following five reasons why I recommend the MEFU cutting machine:

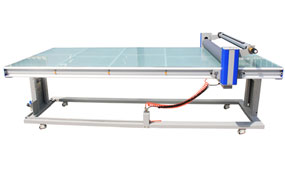

First, the working principle of the MEFU material cutting machine:

The MEFU material cutting machine is a kind of CNC cutting equipment. Its working principle is to control the tool to move on the surface of the material to realize the cutting of the material. MEFU cutting machine accurately controls the movement trajectory and cutting depth of the tool according to the pre-set cutting path and parameters, thus realizing efficient and accurate material cutting.

Second, the advantages and characteristics of the MEFU material cutter:

1. Intelligent edge finding and positioning function.

2. XY dual-axis automatic deskew function.

3. Configuration of internal sensors to help achieve more accurate cutting.

4. Front and rear control panel, equipped with a foot pedal for easy operation.

Third, how to choose the right MEFU material cutting machine for your needs?

- MEFU 1700-XA: Ideal finishing machine for flexible and rigid materials, horizontal electric trimmer for bi-directional cutting, pneumatic cutting system.

- MEFU XY A20: Cuts up to 60 square meters per hour within 0.5 mm error, automatic XY dual-axis guiding, small footprint, ideal for many who need a small cutting machine.

- MEFU 1700-F1 Plus laminating and cutting machine: It has five advantages.

- Rapid automatic leveling in case of wrinkled film.

- Screen a key adsorption operating platform to avoid the screen from appearing rolled edges or warping.

- Air-rise shaft gear type 360-degree jamming, no need for alignment.

- Longitudinal cutting automatic deviation correction, automatic recycling of waste materials.

- Receiving and discharging system adopts magnetic powder clutch; the probe senses the size of the roll diameter and adjusts the tension automatically.

- MEFU A29: Can place 40 KT boards at one time, automatic board feeding, laminating, cutting, fully automatic integration. It is the most cost-effective board cutting machine.

- MEFU A30: The upgraded version of A29. In addition to automatic feeding, laminating, and cutting functions, it can also realize automatic correction of cutting, longitudinal splicing, and transverse overlapping.

The two cutters, A29 and A30, are dedicated to sheet cutting and are the best choice for many wedding companies and large signage companies.

Fourth, maintenance of the MEFU material cutting machine key guidelines:

1. The person who operates the machine must have a comprehensive understanding of the main structure of the machine, performance, operating methods, and conditions that need to be trained randomly. After passing the test, only then operate the machine.

2. Comply with all warning signs affixed to the equipment to improve safety awareness and prevent accidents to protect the operator's personal safety.

3. The power supply used by the equipment must be the same as the type specified on the nameplate. The grounding must be accurate and reliable (equipment using a three-stage plug must not arbitrarily change the function of the grounding pole).

4. When opening the chassis cover of the maintenance equipment, cut off the power supply first to prevent electric shock or mechanical injury. After work is completed, also cut off the power supply.

5. The power cord should not be placed on pedestrian walkways or in areas where it can be rolled over by vehicles.

6. The workplace should be dry and ventilated and should not be close to water sources or wet areas. Equipment should not be stacked near flammable or explosive substances.

7. When more than two people operate the machine, they should coordinate with each other. In case of emergency, staff should press the emergency stop switch in time to stop the machine.

8. The upper rubber roller of the machine is a heated rubber roller with a surface temperature exceeding 100°C. Do not touch the surface with bare skin when heated, and do not put hands or other body parts close to the parts between the rubber rollers to prevent injuries or burns.

9. To extend the service life of the rubber rollers, ensure they are clean. After work is completed, use cotton flannel dipped in 80% alcohol or detergent to wipe them.

10. Do not use water to clean the machine to prevent short circuits, electric shocks, and rust.

11. Regularly check whether rotating parts are flexible and add high-temperature resistant grease to lubricate bearings at both ends of the heated rubber roller.

12. Regularly check that power supply and foot switch wires are not broken to prevent leakage accidents.

It is worth noting that MEFU's after-sales team is dedicated to providing professional and comprehensive technical service and support to every user. When you need us, please contact your local distributor or contact us directly!

Fifth, MEFU material cutting machine in the automation industry application prospects:

The MEFU material cutting machine has broad application prospects in the automation industry. With increasing industrial automation, material cutting machines play a vital role in production lines. The MEFU material cutting machine has characteristics such as high precision, high efficiency, and high reliability that can meet automated production line demands for material cutting.

In the automation industry, MEFU material cutting machines can be widely used in various industries such as poster and banner design, wedding planning, advertising and promotional signage graphics protection, construction industry, and many other fields. They can achieve precise cutting of various materials, improve production efficiency, reduce labor costs, ensure product quality, and maintain production stability.